As industries worldwide seek lightweight and durable solutions, carbon fibre pipes have emerged as a superior choice. With a market growth rate of 15% in 2023, the demand for these high-performance pipes is soaring, highlighting their critical role in modern engineering.

Understanding Carbon Fibre Pipes

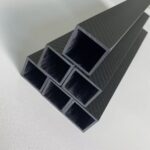

What is a Carbon Fibre Pipe?

A carbon fibre pipe is composed of carbon fibres embedded in a resin matrix, offering exceptional strength-to-weight ratio compared to traditional materials like steel or fiberglass. These pipes are renowned for their lightweight nature and superior mechanical properties, making them ideal for applications where performance and efficiency are paramount.

Advantages of Carbon Fibre Pipes

Carbon fibre pipes offer numerous advantages:

Lightweight and High Strength: They provide the same strength as metal pipes but at a fraction of the weight.

Corrosion Resistance: Unlike metal, carbon fibre does not corrode, ensuring longevity.

Temperature Resistance: They maintain integrity under high temperatures, suitable for various industrial processes.

Reduced Maintenance Costs: Their durability translates to lower maintenance and replacement costs over time.

Materials and Tools Needed

Carbon Fibre Materials

Selecting the right carbon fibre materials is crucial. High-quality carbon fibre cloths are available in different weaves and thicknesses, each suited for specific applications. Understanding the properties of various carbon fibres ensures the final product meets the desired performance criteria.

Resins and Epoxies

Resins, particularly epoxy, play a vital role in binding carbon fibres together. Choosing the appropriate resin ensures optimal bonding and enhances the mechanical properties of the pipe. The selection process involves considering factors like curing time, temperature resistance, and flexibility.

Tools and Equipment

Manufacturing carbon fibre pipes requires specialized tools and equipment:

Molds: Precision molds shape the pipes accurately.

Vacuum Bags: Used in the vacuum-assisted resin transfer molding (VARTM) process to ensure even resin distribution.

Cutting and Finishing Tools: For trimming and finishing the pipes to the desired specifications.

Common Mistakes to Avoid

Avoiding common manufacturing mistakes can enhance product quality:

Inadequate resin distribution leading to weak spots.

Improper curing temperatures causing defects.

Poor mold preparation resulting in inaccurate dimensions