엔지니어와 재료 과학자들이 수십 년 동안 해부해 온 논쟁을 해결해 봅시다: 매끄럽고 가벼운 탄소 섬유 로드 강도가 기존 강철보다 정말 뛰어날까요? 그 답은 단순한 "예" 또는 "아니오"가 아니라 물리학, 혁신, 그리고 현실 세계의 트레이드오프에 관한 이야기입니다.

재료의 강도 이해

대부분의 사람들은 힘에 대해 이야기할 때 무차별적인 힘을 상상합니다. 하지만 강철과 탄소 섬유 막대 인장 강도, 강성, 무게 효율성 등 여러 측면에서 경쟁을 벌이고 있습니다.

1. "힘"의 진정한 의미는 무엇인가요?

강도는 일차원적인 것이 아닙니다. 강철은 압축 강도(압축에 대한 저항력)가 뛰어나지만, 탄소 섬유 막대 인장 강도(장력에 대한 저항력)가 뛰어납니다. 예를 들어 탄소 섬유의 인장 강도는 다음과 같습니다. 500KSI(평방인치당 천 파운드)연강의 5배 이상입니다.

2. 탄소 섬유와 강철의 과학적 차이

핵심은 여기에 있습니다: 탄소 섬유는 70% 더 가벼워진 무게 강철과 비슷하거나 그 이상의 강도를 자랑합니다. 항공 우주와 같은 산업에서 이는 최대 다음을 의미합니다. 20% 연료 절감 - 게임 체인저

3. 고려해야 할 제한 사항

탄소 섬유는 극한의 열(400°F 이상)과 갑작스러운 충격에 견디기 어렵습니다. 강철은 여전히 고온 기계류의 왕입니다.

액션 어스: 신뢰할 수 있는 탄소 섬유 제조업체와의 파트너십

웨이하이 롱허 컴포지트에서는 10년 이상 OEM을 완성하기 위해 노력해 왔습니다. 탄소 섬유 막대 강도, 무게, 경제성이 균형을 이루는 제품입니다.

왜 우리와 함께 일해야 하나요?

✅ 최소 주문 수량: 소규모로 시작하여 자신 있게 확장하세요.

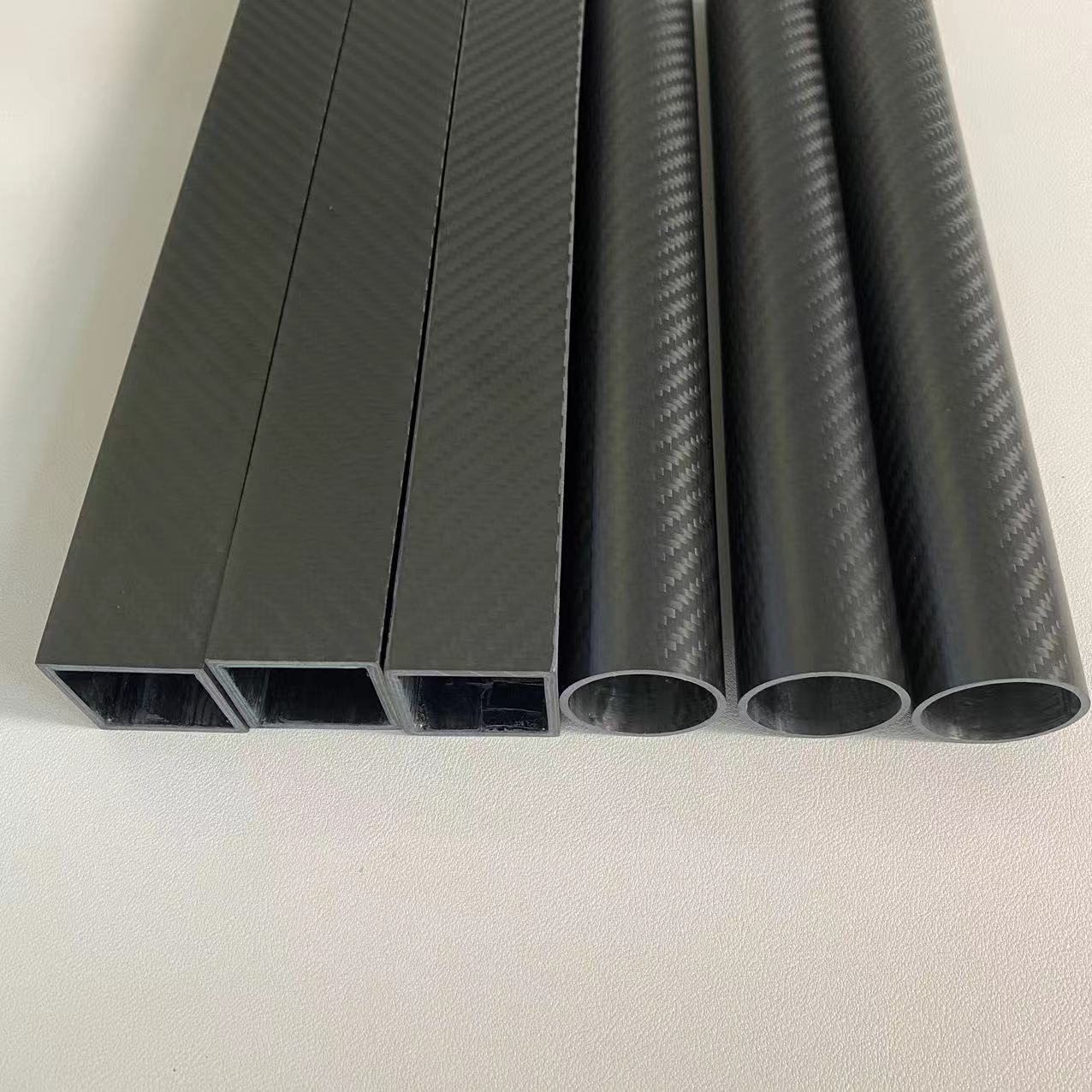

✅ 맞춤형 솔루션: 맞춤형 직경, 코팅 및 길이.

✅ 신속한 배송: 표준 주문의 경우 15일 소요.