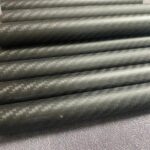

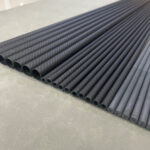

The carbon fiber market is expected to reach $10.7 billion by 2030, driven by industries such as aerospace, automotive, and robotics. Lightweight, durable and versatile, 탄소 섬유 튜브 are reshaping the way engineers and designers innovate. But with so many suppliers claiming to offer “quality products,” how do you choose the right partner?

At JINAN and WeiHai LongHe, we’ve spent more than a decade perfecting the production process for carbon fiber tubes and custom components. Whether it’s prototyping a cutting-edge drone or expanding the production of an electric vehicle, we deliver superior products, which is why discerning buyers trust us.

Four Reasons to Work with a Trusted Carbon Fiber Supplier

1. Minimum Order Quantity (MOQ) Flexibility

Startups and corporations face a common challenge: balancing budget constraints with quality. Unlike suppliers who adhere to strict minimum order quantities, we can meet the needs of projects of all sizes. Only need 50 test units? We can meet your needs. Scaling up to 10,000? Let’s optimize costs together.

2. Expertise backed by a dedicated technical team

Carbon fiber is not just a material, it’s a science. Our engineers have solved complex problems for customers in over 15 countries, from optimizing wall thickness for load-bearing applications to ensuring perfect resin infusion. Have a technical question? Our team will respond within 24 hours.

3. Fast delivery, no compromises

Time-to-market can make or break a product. We’ve streamlined our production process to reduce lead times by 30% compared to the industry average. How? State-of-the-art automation, strategic stockpiling of raw materials, and a logistics network in Asia, Europe, and North America.

4. Options tailored to your needs

Standard sizes don’t fit? We specialize in customized solutions. You can choose from

- Diameters from 2 mm to 300 mm

- Customized weaves (plain, twill, unidirectional)

- Resin systems (epoxy, thermoplastic, flame retardant)

- Finishes (glossy, matte, textured)