Introduction to Carbon Fiber Strain

Carbon fiber, a material known for its strength and lightweight properties, is increasingly used in various industries. Understanding its behavior, particularly the carbon fiber strain under different conditions, is crucial for optimizing its use.

What is Carbon Fiber Weed Strain?

While the term carbon fiber weed strain may seem unrelated, it highlights the diverse applications and interpretations of carbon fiber technology, including in less traditional fields.

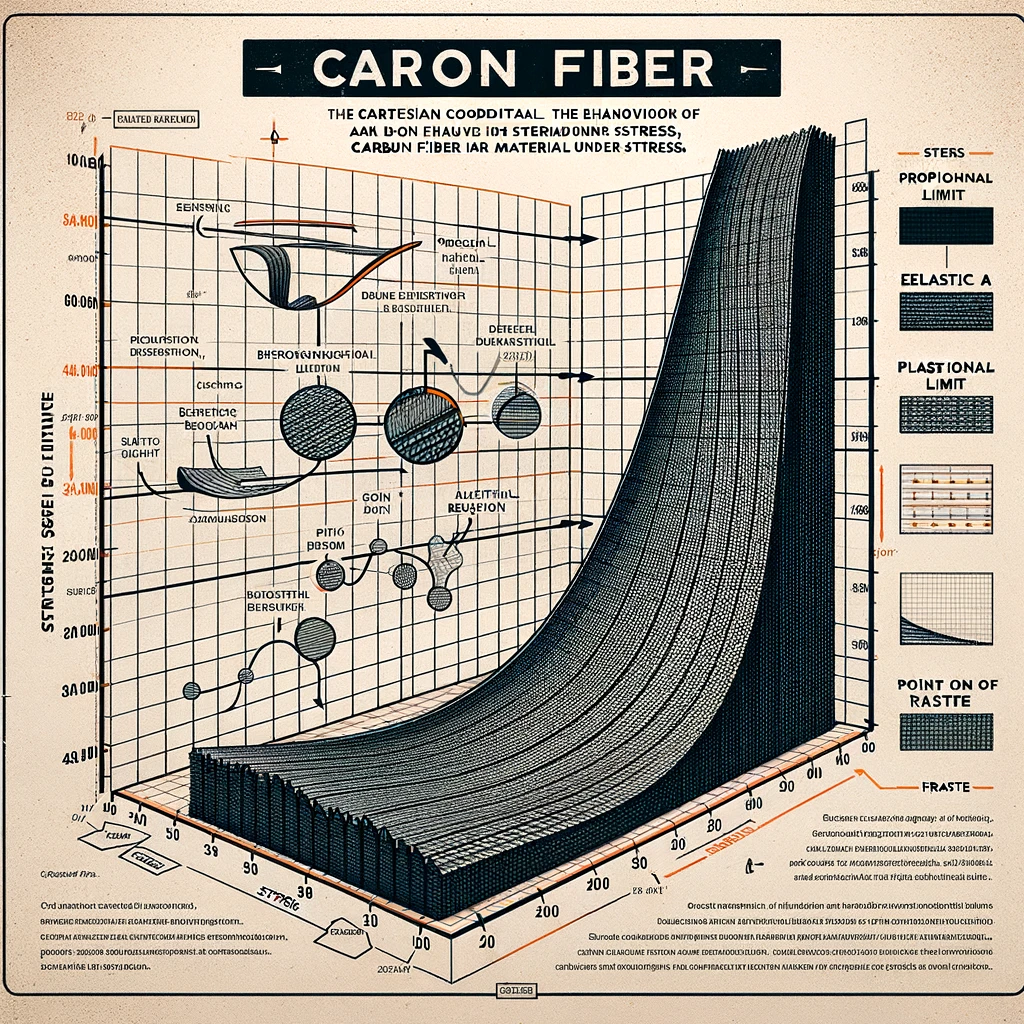

Carbon Fiber Stress Strain Curve Explained

Le carbon fiber stress strain curve is a fundamental aspect of material science. This section will delve into its significance, providing graphs and explanations to illustrate how carbon fiber behaves under stress.

The Science Behind Carbon Fiber Strain

Analyzing the scientific principles behind carbon fiber strain, this part will explore the material’s response to external forces and its inherent structural properties that dictate this behavior.

Here is the diagram explaining the Carbon Fiber Stress Strain Curve. It features a Cartesian coordinate system with stress on the vertical axis and strain on the horizontal axis, illustrating the typical behavior of carbon fiber material under stress, including regions such as the proportional limit, elastic region, plastic region, and point of fracture. This graph is clearly labeled and designed to be informative for both educational and industrial contexts.

Applications of Carbon Fiber Strain in Industry

From aerospace to automotive industries, the application of carbon fiber’s strain characteristics is wide-ranging. We’ll examine how understanding this aspect can lead to groundbreaking developments.

Challenges and Future of Carbon Fiber Strain Research

Current Challenges:

- Material Heterogeneity: Carbon fiber composites are inherently heterogeneous, which makes predicting their behavior under stress and strain complex. This heterogeneity can lead to variations in performance and reliability.

- Understanding Microscale Mechanics: The micro-mechanics of carbon fibers, particularly how individual fibers interact with the matrix material, are not fully understood. This gap in knowledge limits advancements in enhancing strength and durability.

- Cost and Manufacturing Efficiency: High production costs and complex manufacturing processes restrict broader applications of carbon fiber materials. Finding cost-effective and scalable manufacturing methods remains a significant challenge.

- Environmental Impact: The production of carbon fibers is energy-intensive and often involves non-renewable resources. There is a growing need for more sustainable production processes and recycling methods for carbon fiber composites.

- Damage Detection and Repair: Identifying and repairing internal damage within carbon fiber composites can be challenging. Developing non-destructive evaluation techniques and effective repair methods is crucial for long-term usage.

Future Directions:

- Nanotechnology Integration: Utilizing nanotechnology could enhance the properties of carbon fibers, such as incorporating nanoparticles to improve mechanical properties or conductivity.

- Advanced Simulation and Modeling: Developing more sophisticated simulation models that can accurately predict the behavior of carbon fiber composites under various conditions will be a key area of research. This includes the use of AI and machine learning for material analysis.

- Sustainable Manufacturing: Research into eco-friendly production methods and materials, as well as recycling and reuse of carbon fiber composites, will be increasingly important.

- Hybrid Material Development: Combining carbon fibers with other materials to create hybrid composites that capitalize on the strengths of each component can lead to new applications and performance enhancements.

- Expanded Applications: Exploring and developing new applications in sectors such as renewable energy (e.g., wind turbine blades), automotive, aerospace, and construction could drive innovation and demand.

- Collaboration and Standardization: Increased collaboration between industry, academia, and regulatory bodies to standardize testing methods and quality control measures will help in advancing the field.