Engaging Introduction

In a world where technology continues to push the boundaries of what is possible, carbon fiber materials stand out as the benchmark for innovation in manufacturing. With its high strength and lightweight properties, carbon fiber products are revolutionizing a number of industries, from automotive to aerospace. In this article, we’ll take an in-depth look at how to choose the right carbon fiber sheets and tubes for your specific needs, ensuring that you’re utilizing the full potential of this extraordinary material.

Understanding the Basics of Carbon Fiber

Praised for its exceptional strength-to-weight ratio and rigidity, carbon fiber has become a cornerstone of advanced materials engineering. As industries strive for lighter and stronger materials, carbon fiber is often the focus of discussion. But what makes carbon fiber truly unique? That’s the arrangement of the carbon atoms, which are tightly bound in microscopic crystals and organized along the fiber’s long axis. This arrangement gives carbon fiber its incredible strength and enables it to be made into a variety of profiles, including carbon fiber sheets and carbon fiber tubing.

How to choose the right carbon fiber sheet

Choosing the right carbon fiber sheet involves understanding the specific properties that match the needs of your application. Consider factors such as tensile strength, flexibility and heat resistance. Each parameter will determine how carbon fiber will perform in different environments. For example, in the automotive industry, there may be a greater focus on high tensile strength to withstand harsh use; whereas in consumer electronics, flexibility and weight may be more important.

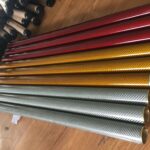

Innovations and Options in Carbon Fiber Tubing

Carbon fiber tubing offers versatile solutions for many structural and aesthetic applications. From bicycle frames to drone fuselages, the choice of fiber orientation, diameter and wall thickness affects the performance of the tubing. Understanding load requirements and environmental factors will guide you in selecting the right type of tubing for your project!