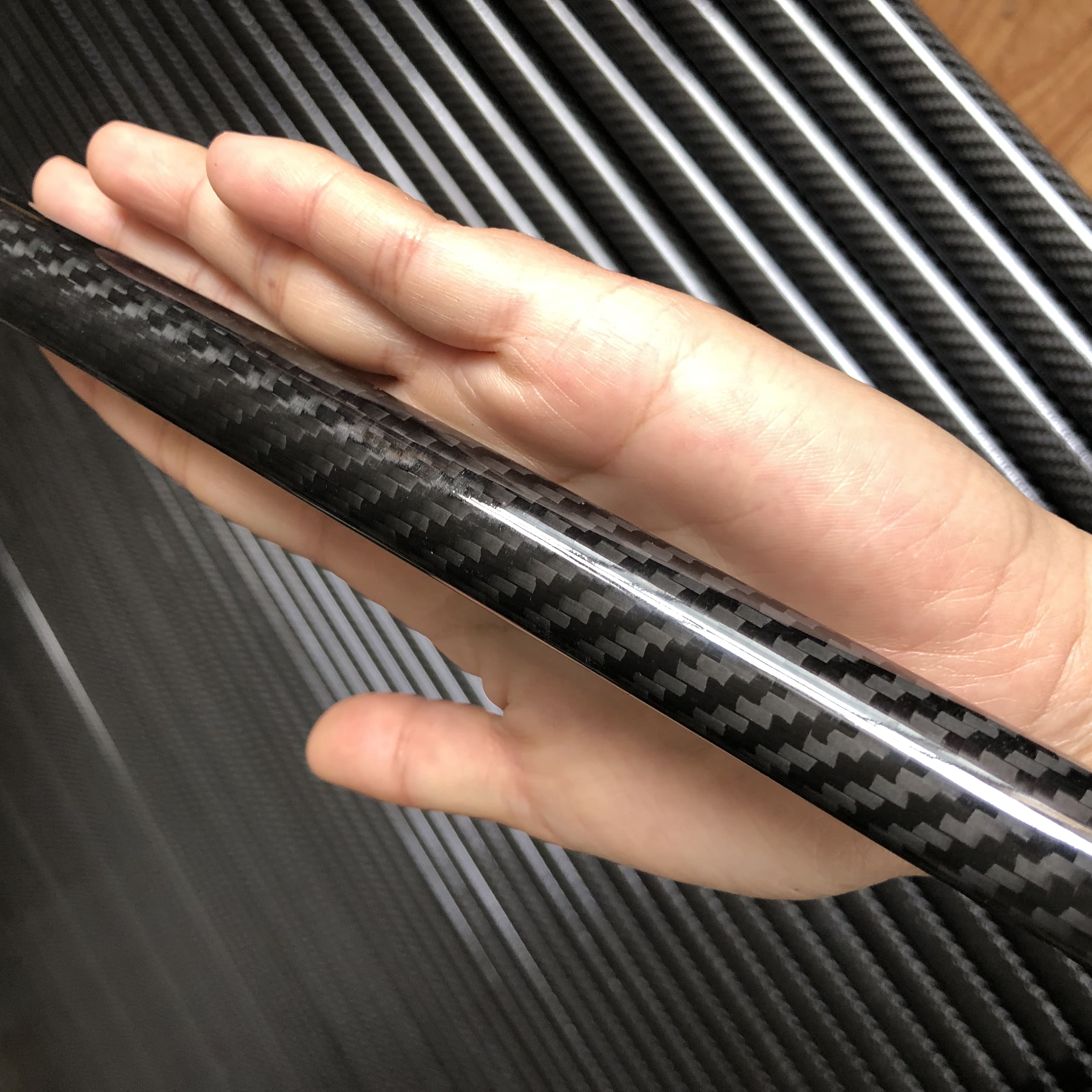

Telescoping carbon fiber tubes have an extremely high strength-to-weight ratio and are unbeatable in terms of their advantages, making them ideal for a wide range of applications. But how are these tubes connected to the different components? Let’s take a closer look at the connection technology that is setting waves in all kinds of industries.

A closer look at carbon tube connectors

Telescopic tube clamp: This connector allows the carbon tubes to slide against each other and is held in place by a clamp, the length of which can be easily adjusted.

Telescopic tube twist lock: This lock uses a twisting mechanism that ensures a tight connection with just a simple twist, for a quick and secure connection.

Telescopic tube spine button: The spine button system allows the telescopic tube to be quickly locked and unlocked with a push-button mechanism, for quick assembly and disassembly.

Telescopic tube screw: The screw is used to connect the ends of the carbon fiber tube end-to-end, and a screw adapter is provided for a secure permanent connection.

Tapered telescopic tubes: This method involves tubes with tapered ends that fit together tightly to form a smooth, streamlined joint without the need for external hardware.

Choosing the Right Connector for Your Project

Ask yourself:

- Adjustability needed? Twist locks for speed, clamps for precision.

- Load capacity? Tapered designs handle heavy axial loads.

- Environment? Saltwater or extreme temps? Opt for corrosion-resistant alloys.