Last year, colored composites accounted for 23% of all specialty material requests according to Composites World’s market report. At Weihai Longhe Composite, we’ve seen firsthand how red and black carbon fiber combinations transform racing components into brand statements, while aerospace engineers specify colored carbon fiber tubes for corrosion-resistant marine applications.

Beyond Basic Black: The Growing Demand for Colored Composites

When BMW unveiled their M4 GT3 with custom yellow carbon fiber accents, it wasn’t just about aesthetics. Colored composites solve practical challenges – from UV resistance in white carbon fiber medical devices to brand-aligned green carbon fiber components in eco-tech products.

Our technical team handles more than 150 color requests per year. “The right hue can increase product recognition by up to 40%,” notes our chief engineer. “But it’s more than just dipping; true color integration requires expertise in materials science.

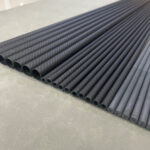

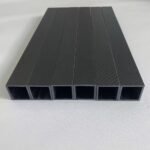

Colored Carbon Fiber Tubes

1. Red and Black Carbon Fiber: The Classic Performance Statement

The signature look for high-performance automotive parts. Our proprietary resin system achieves deep, fade-resistant tones while maintaining strength.

2. Yellow Carbon Fiber: High-Visibility Solutions

It is an essential material for safety components of ships and industrial equipment.

3. Blue Carbon Fiber: Marine & Aerospace Applications

The salt water resistant finish makes our blue carbon fiber tubes ideal for yacht rigging and drone frames.

4. Green Carbon Fiber: An Eco-Conscious Brand

Popular in consumer electronics and electric vehicle components.

5. White Carbon Fiber: Clean Aesthetic Appeal

Medical grade finish, stain resistant

The Science Behind Colored Carbon Fiber Tubes

We use resin transfer molding (RTM) with pre-colored epoxy systems rather than surface coatings. This ensures:

- Uniform color penetration

- No delamination risks

- Maintained 1.5:1 strength-to-weight ratio